Scheme Introduction

Industrial automation control system refers to the industrial production process and its mechanical and electrical equipment, process equipment measurement and control of the automation technology tools. Due to the industrial automation system is distributed, real-time intelligent control development, with the rapid development of information technology at the same time, require companies from the field control layer to the management to achieve the comprehensive seamless information integration, industrial Ethernet technology provides an open complete infrastructure, to meet the industry control field, and the urgent need of unified communication protocol and network It has been widely promoted and applied, and will become the development direction of industrial control communication in the future.

Scheme Advantage

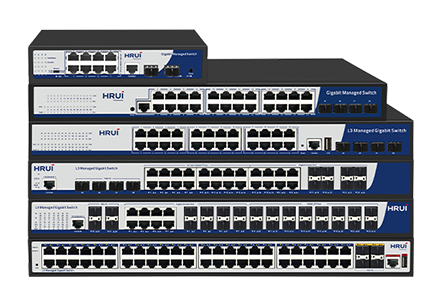

· Support optical fiber networking and photoelectric hybrid transmission, to achieve a large range, long distance, anti-interference network communication coverage.

· Open-race switching, full-line fast forwarding of products, to meet the requirements of large traffic, high bandwidth, low delay and other data transmission.

· Dual power redundancy design, in case of power failure, can ensure a more durable and stable power supply.

· A variety of ring network types, rich networking mode, to meet the needs of industrial networking and communication control, convenient network expansion.

· The ringnetwork self-healing technology is adopted, and the loop network self-healing time is less than or equal to 12ms to ensure the rapid healing of the transmission network in case of link failure.

· Supports Bypass Bypass protection to avoid full resistance caused by single point of failure and improve network reliability.

· Industrial construction design, no fan, support DIN and rail mounting, strong protective housing, IP40 standard.

· Lightning and static, strong electromagnetic interference and surge resistance, working temperature: -40~85°C and adapts to various harsh environments.